From installation to training to ongoing maintenance, our team of experts is here to help you every step of the way. With our Eagle Fiber Laser 30kw systems, you can expect nothing but the best in performance and reliability.

Designed for efficiency and durability, these machines are built to tackle even the toughest cutting tasks with ease. And with our Falcon Laser Gun systems, you can expect nothing but the best in performance and durability.

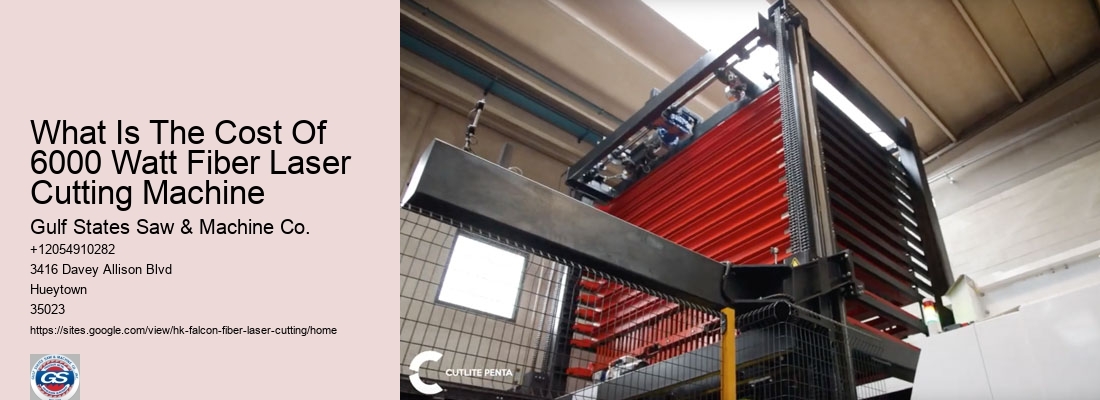

Whether you're working in a demanding industrial environment or a high-volume production facility, our Falcon Laser systems are up to the challenge. Revolutionizing precision cutting in industrial environments, HK Falcon Fiber Laser Cutting Systems represent the pinnacle of advanced technology. These cutting-edge machines, crafted by HK, seamlessly integrate fiber laser technology to achieve unparalleled efficiency, accuracy, and speed. With their high-powered lasers and precise motion control mechanisms, Falcon systems are adept at cutting through various materials, including metals, alloys, and composites. Beyond their cutting prowess, these systems feature intuitive user interfaces, making them accessible to operators across industries such as automotive, aerospace, electronics, and signage. With HK Falcon Fiber Laser Cutting Systems, businesses can elevate their production capabilities, ensuring faster turnaround times and superior quality outputs.. With our Universal Fiber Laser solutions, you can stay ahead of the competition and achieve your manufacturing goals with confidence.

Service TrainingTrust Gulf States Saw & Machine Co. for all your cutting needs, and experience the difference that quality and innovation can make. Contact us today to learn more about our products and services, and let us help take your business to new heights.

Gulf States Saw & Machine Co. is your trusted source for Hk Falcon Fiber Laser Cutting Systems.

Our Hk Fiber Laser machines are engineered for precision and efficiency, delivering unmatched performance and reliability. Whether you're cutting stainless steel, aluminum, copper, or brass, our Falcon Laser systems are up to the task, providing exceptional results every time.

FurnitureBut it's not just about performance – it's also about support. That's why Gulf States Saw & Machine Co. is committed to providing comprehensive services to ensure that your operations run smoothly.

From installation to training to ongoing maintenance, our team of experts is here to help you every step of the way.

Designed for efficiency and durability, these machines are built to tackle even the toughest cutting tasks with ease. And with our Falcon Laser Gun systems, you can expect nothing but the best in performance and durability.

Whether you're working in a demanding industrial environment or a high-volume production facility, our Falcon Laser systems are up to the challenge.

Trust Gulf States Saw & Machine Co. for all your cutting needs, and experience the difference that quality and innovation can make. Contact us today to learn more about our products and services, and let us help take your business to new heights.

Welcome to Gulf States Saw & Machine Co., where innovation meets precision in industrial cutting solutions.

Experience the power of our Hk Fiber Laser machines, engineered to deliver unmatched precision and efficiency in every cut. From stainless steel to aluminum, copper to brass, our Falcon Laser systems handle a diverse range of materials with ease.

Discover our comprehensive range of Hk Laser Cutting Machines, tailored to meet your specific needs and budget. Robustness Whether you're looking for an entry-level model or a high-powered industrial system, we have the perfect solution for you.

But our commitment doesn't end with the sale. Advanced At Gulf States Saw & Machine Co., we provide comprehensive support and services to ensure that your operations run smoothly. From installation to training to ongoing maintenance, our team of experts is here to assist you every step of the way.

Unleash your creativity with our Eagle Fiber Laser 30kw systems, designed to tackle even the most challenging cutting tasks with ease. Built for durability and reliability, our Falcon Laser Gun systems deliver consistent performance in demanding industrial environments.

Stay ahead of the competition with our Universal Fiber Laser solutions, designed to meet the evolving needs of modern manufacturing. Trust Gulf States Saw & Machine Co. for all your cutting needs, and experience the difference that quality and innovation can make.

Contact us today to learn more about our products and services, and let us help take your business to new heights.

Welcome to Gulf States Saw & Machine Co., your trusted partner for Hk Falcon Fiber Laser Cutting Systems. With our cutting-edge technology and commitment to excellence, we deliver precision and performance that exceed expectations.

Experience the versatility of our Hk Fiber Laser machines, capable of handling a wide range of materials with ease. From stainless steel to aluminum, copper to brass, our Falcon Laser systems deliver exceptional results every time.

Explore our range of Hk Laser Cutting Machines, designed to meet the diverse needs of modern manufacturing.

Yes, the HK Falcon Fiber Laser Cutting System is capable of cutting intricate designs and complex shapes with high accuracy.

Installation time can vary depending on factors such as size, configuration, and site preparation requirements.

Yes, the HK Falcon Fiber Laser Cutting System can be customized with various options and accessories to meet specific industry requirements.

Yes, fiber laser technology is environmentally friendly, producing minimal waste and emissions compared to other cutting methods.

Energy consumption is relatively low compared to traditional cutting methods, making it cost-effective and efficient.